Ljuds™ prism-shaped wood wool panels, 173mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Ljuds™

Ljuds™ wood wool acoustic panels are made from recyclable wood fibers, cement, and water, offering a sustainable and formaldehyde-free solution. These acoustic panels improve sound absorption while complementing any space with natural facade materials. Ideal for acoustic treatment these sustainable wall panels elevate both acoustic design and performance in various environments.

Products

Diagonal 300

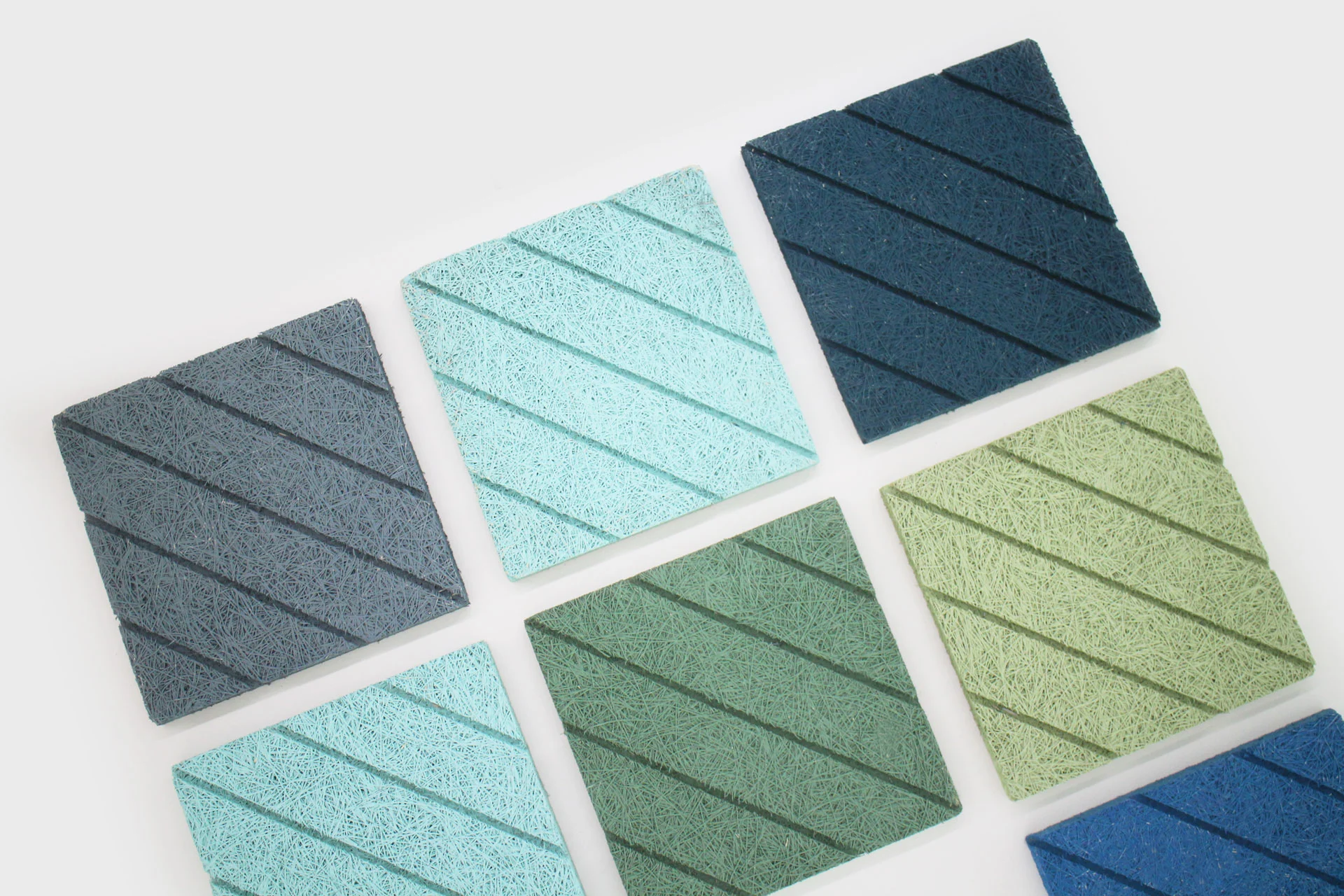

Ljuds™ Diagonal 300 panels, 300mmW x 300mmH, feature grooved lines for dynamic geometric patterns, providing sound absorption and moisture regulation.

Diagonal 600

Ljuds™ Diagonal 600 panels, 600mmW x 600mmH, feature grooved lines for dynamic geometric patterns, providing sound absorption and moisture regulation.

Diagonal 1200

Ljuds™ Diagonal 1200 panels, 600mmW x 1200mmH, feature grooved lines for dynamic patterns, offering sound absorption and moisture control in modern interior environments.

Loop 300

Ljuds™ Loop 300 panels, 300mmW x 300mmH, feature circular grooves for a textured design, providing sound absorption and moisture regulation.

Loop 600

Ljuds™ Loop 600 panels, 600mmW x 600mmH, feature circular grooves for a textured design, providing sound absorption and moisture regulation.

Loop 1200

Ljuds™ Loop 1200 panels, 600mmW x 1200mmH, feature circular grooves for a textured design, providing sound absorption and moisture regulation.

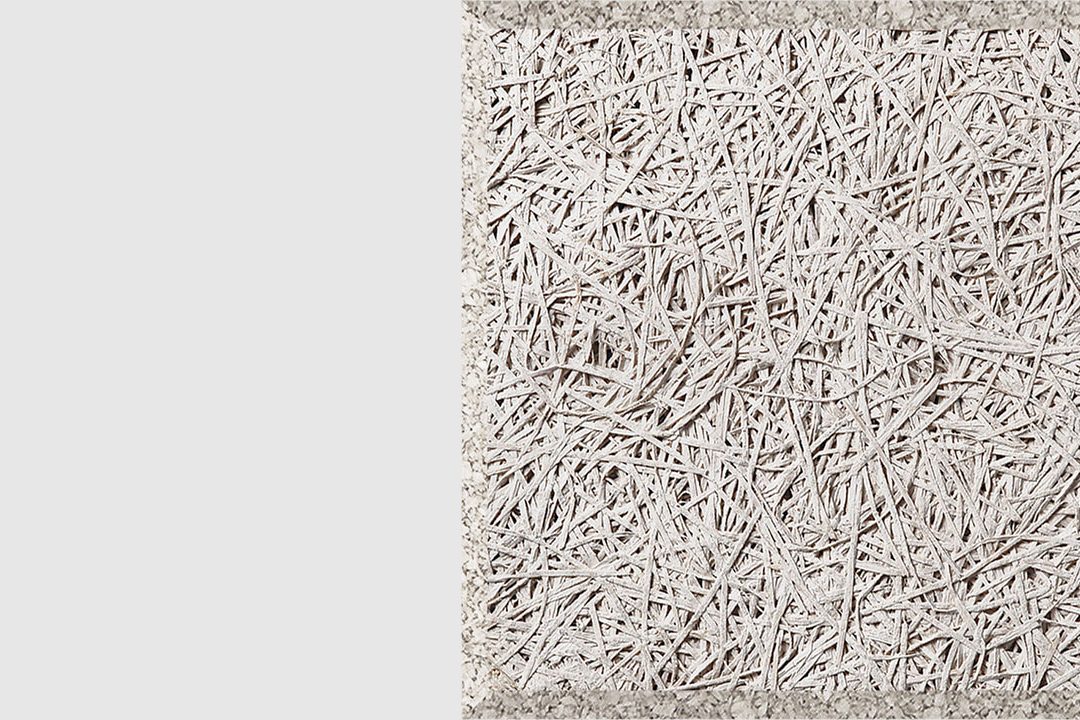

Circuit

juds™ circuit wood wool panels, 600mmW x 1200mmH, are eco-friendly, sound-absorbing, and moisture-regulating for acoustic performance.

Horizon 75

Ljuds™ Horizon 75 panels, 600mmW x 1200mmH, feature horizontal grooves for a sleek, expansive look, offering sound absorption and moisture control.

Horizon 75L

Ljuds™ Horizon 75L panels, 1200mmW x 2400mmH, feature horizontal grooves for a sleek, expansive look, offering sound absorption and moisture control.

Horizon 150

Ljuds™ Horizon 150 panels, 600mmW x 1200mmH, feature grooved lines for dynamic patterns, offering sound absorption and moisture control.

Horizon 150L

Ljuds™ Horizon 150L panels, 1200mmW x 2400mmH, feature grooved lines for dynamic patterns, offering sound absorption and moisture control.

Vertical 75

Ljuds™ Vertical 75 panels, 600mmW x 1200mmH, feature vertical grooves for added height, with sound absorption and moisture control.

Vertical 75L

Ljuds™ Vertical 75L panels, 1200mmW x 2400mmH, feature vertical grooves for added height, with sound absorption and moisture control.

Vertical 150

Ljuds™ Vertical 150 panels, 600mmW x 1200mmH, feature vertical grooves for added height, with sound absorption and moisture control.

Vertical 150L

Ljuds™ Vertical 150L panels, 1200mmW x 2400mmH, feature vertical grooves for added height, with sound absorption and moisture control.

Circle

Ljuds™ circular wood wool panels, with a size of 300mmD, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Diamond

Ljuds™ diamond-shaped wood wool panels, 173mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

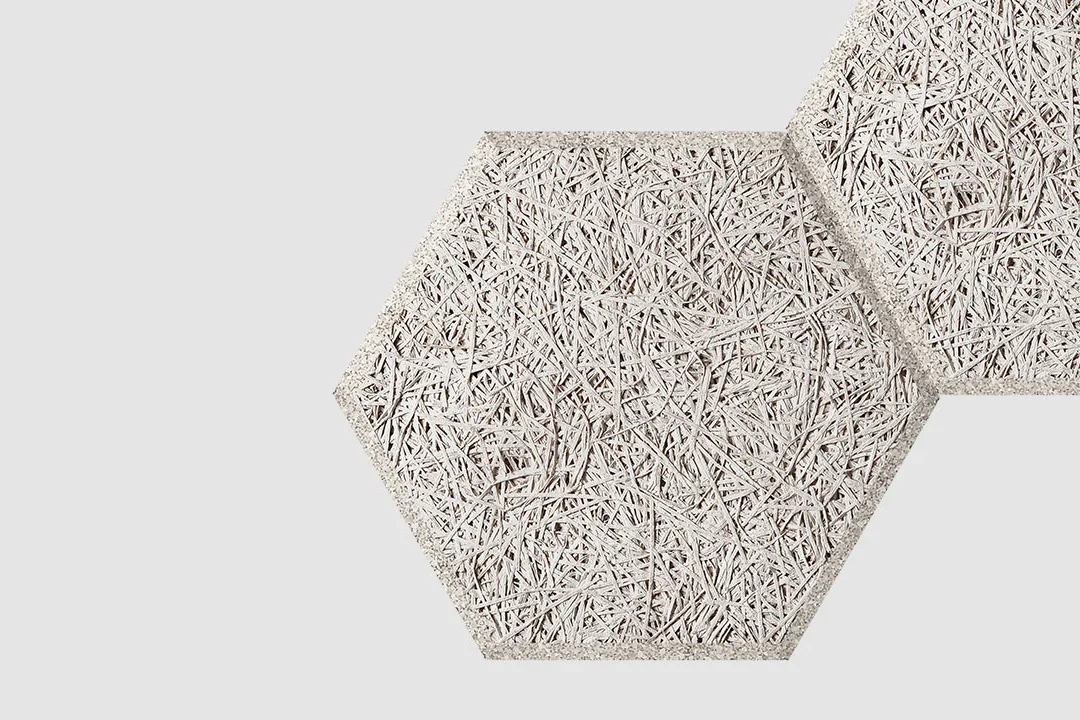

Hexagon

Ljuds™ hexagon-shaped wood wool panels, 259mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Honeycomb

Ljuds™ honeycomb-shaped wood wool panels, 176mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Pentagon

Ljuds™ pentagon-shaped wood wool panels, 173mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Rectangle

Ljuds™ rectangular wood wool panels, 300mmH x 600mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Scale

Ljuds™ scale-shaped wood wool panels, 253mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Square

Ljuds™ square wood wool panels, 300mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

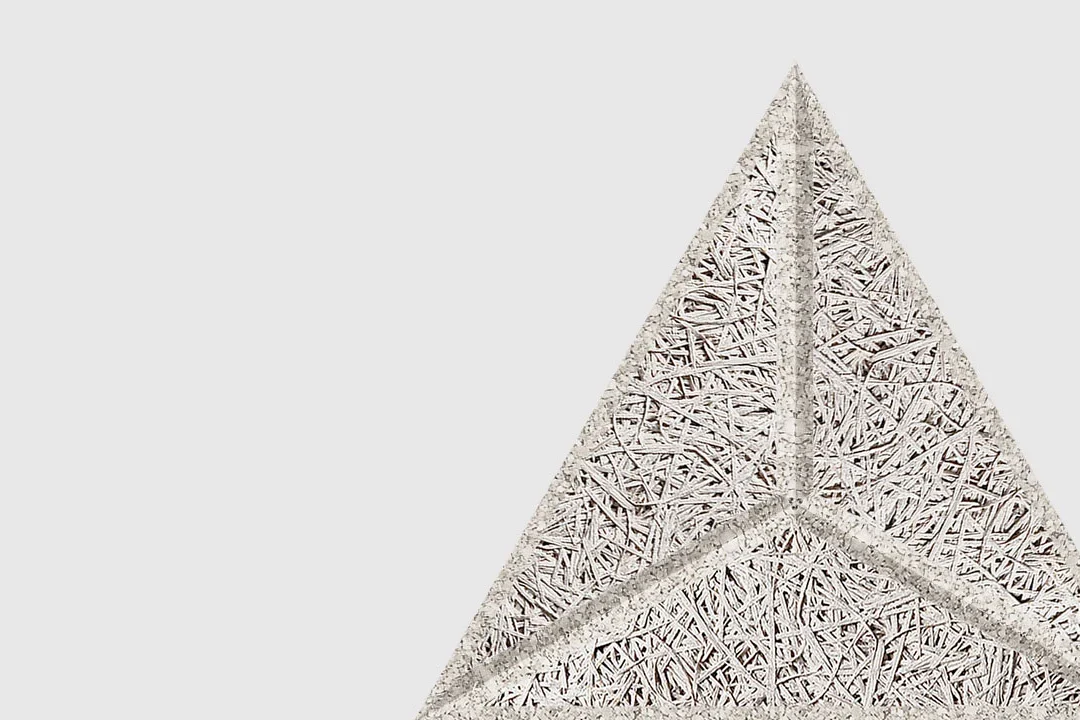

Triangle

Ljuds™ triangular wood wool panels, 300mmH x 300mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

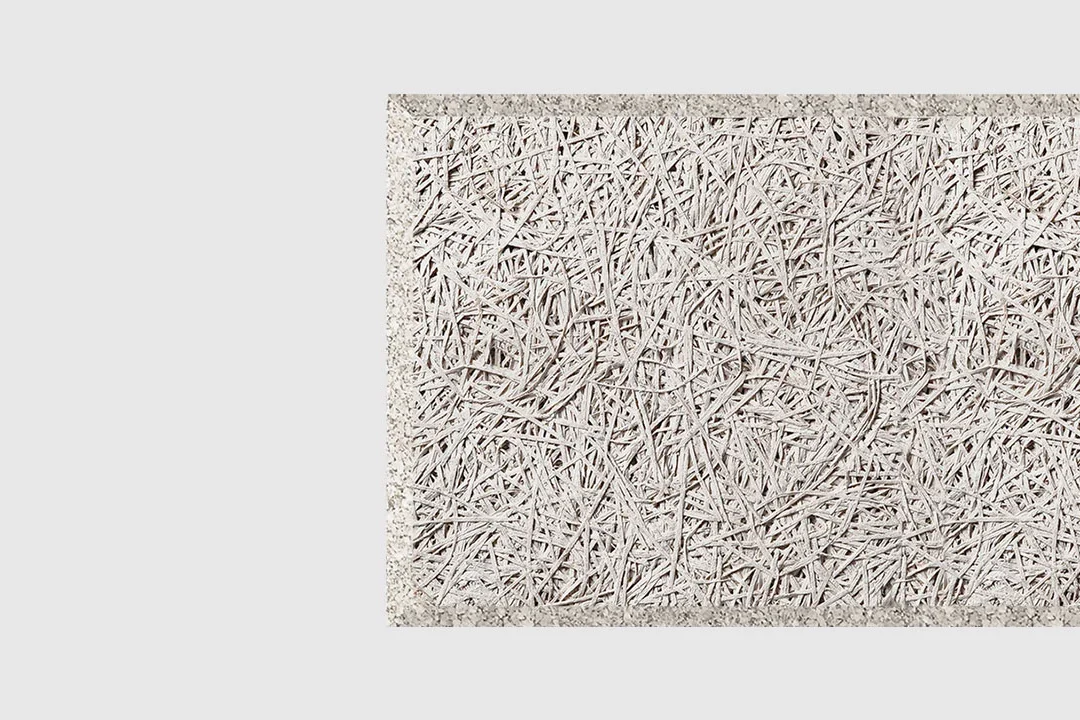

Board

Ljuds™ board-shaped wood wool panels, 1220mmH x 2440mmW, are eco-friendly, sound-absorbing, and moisture-regulating for enhanced acoustic performance.

Project Highlight

Ljuds™ Board

In a space where nature and architecture meet, the oceanarium project required more than just visual impact—it demanded acoustic precision. Designed for immersive learning and tranquil exploration, the venue integrated Ljuds™ panels to soften ambient noise and enrich the visitor experience.

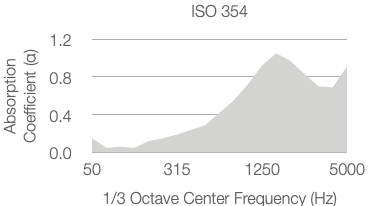

How Does Ljuds™ Wood Wool Acoustic Panel Work?

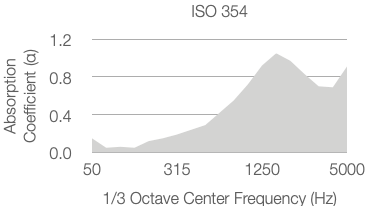

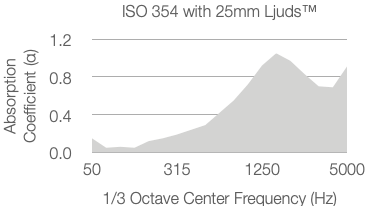

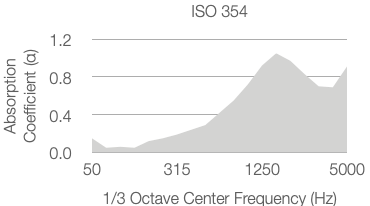

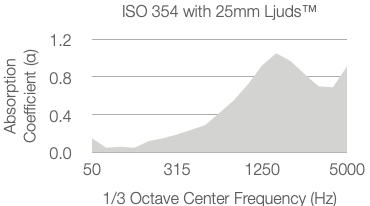

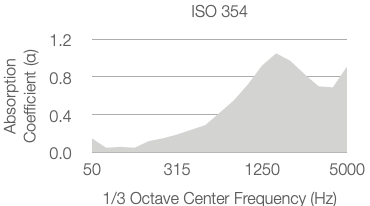

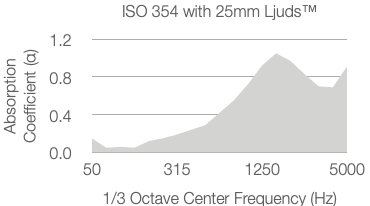

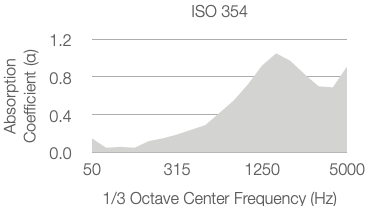

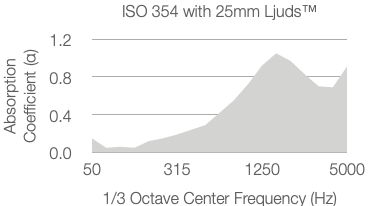

Ljuds™ Wood Wool Acoustic Panels enhance sound absorption through porous wood-fiber surfaces and high-density cement-bonded cores. These systems improve sound control, thermal insulation, and overall comfort in any space. Designed with natural textures and architectural versatility, they elevate interior expression, resist moisture and mold, and deliver long-lasting functional benefits. As an innovation-driven company, Ljuds™ develops wood wool solutions that balance acoustic performance, durability, and refined interior aesthetics.

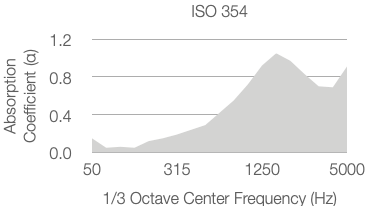

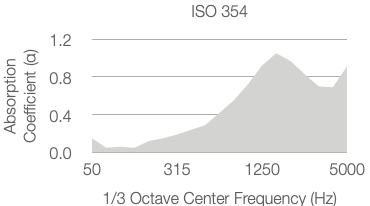

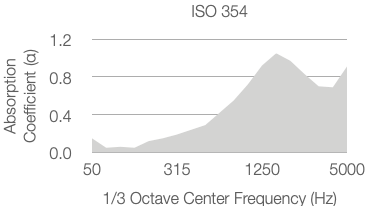

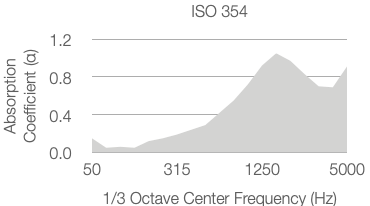

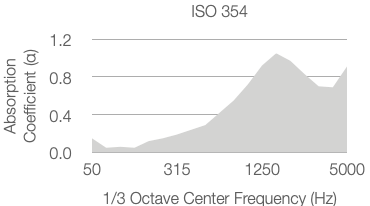

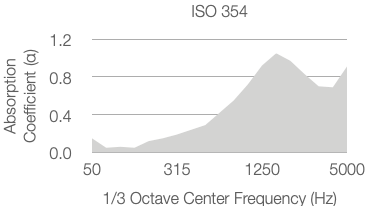

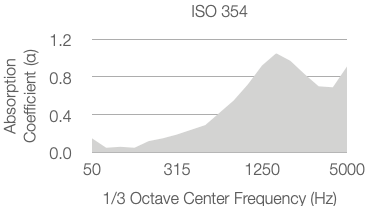

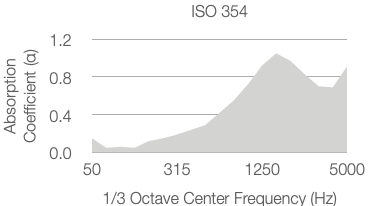

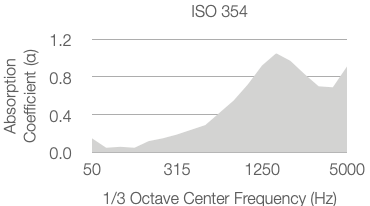

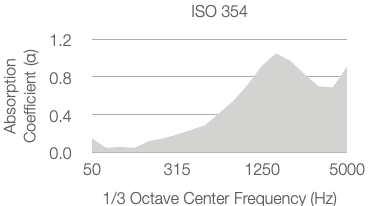

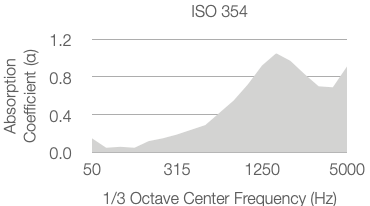

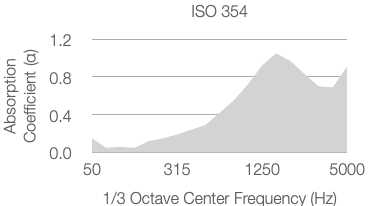

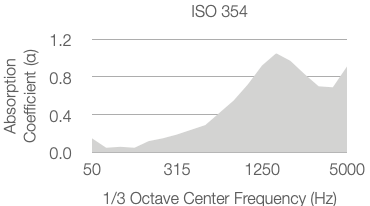

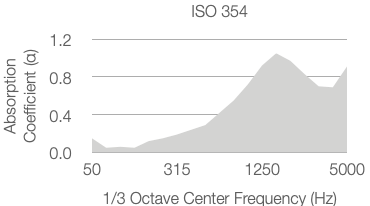

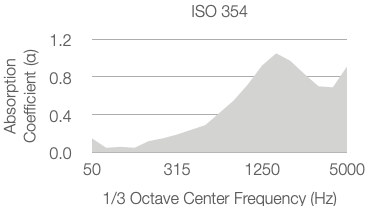

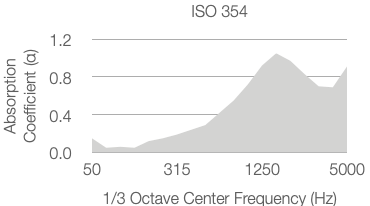

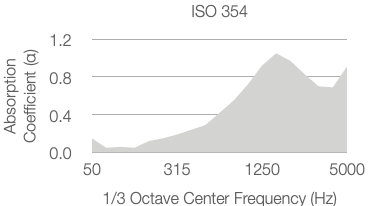

Sound Absorption

In rooms with reflective surfaces and high ceilings, sound waves create echo and excessive reverberation that reduce speech clarity. Ljuds™ Wood Wool Acoustic Panels are engineered to absorb sound, helping control noise levels, improve sound quality and create a comfortable environment in offices, auditoriums, and commercial spaces.

Designed for Architects

Effective acoustics should blend seamlessly with interior design. Ljuds™ Wood Wool Acoustic Panels come in a wide range of natural textures, colors, and panel styles to suit modern offices and public spaces. These wood wool panels integrate sound control without disrupting the visual identity of the room and environment.

Warranty Guaranteed

High-use environments require acoustic systems that last. Ljuds™ Wood Wool Acoustic Panels are engineered with durable, fire-resistant, and eco-conscious materials to deliver consistent acoustic performance. Supported by reliable warranty protection, they provide long-term stability, thermal comfort, and peace of mind for customers.

Standards

Material: Recyclable Wood Fibres in Cement Matrix

Standard Dimension:

300mm x 300mm

600mm x 600mm

1200mm x 2400mm

Standard Thickness:

15mm, 20mm, 25mm

Bevel Dimension: 10mm, 45°

-

Eco-Friendly Test:

EN 13986 = E1 -

Fire Classification Test:

EN 13501-1 = Class B -

Smoke Density Test:

EN 13501-1 = s1 d0

Frequently Asked Questions

Ljuds™ panels are made from recyclable wood fibres combined with a cement matrix and water. This composition creates a sustainable, formaldehyde-free acoustic panel that absorbs sound effectively and regulates indoor moisture and air permeability.

Ljuds™ panels come as wall panels, ceiling tiles, or indoor cladding. Standard panel sizes include 300 × 300 mm or 300 × 600 mm, and standard thicknesses are 25 mm or 50 mm. Panels are also bevel-ed for a clean finish.

Because of their porous wood-fibre structure plus cement matrix, Ljuds™ panels absorb sound waves and reduce reverberation while helping regulate humidity. They thus improve acoustic comfort and support healthier indoor air conditions — useful in offices, homes, public spaces or commercial buildings.

Yes. Ljuds™ panels comply with environmental standard EN 13986 and are rated E1 for low emissions. For fire safety they meet EN 13501-1 Class B s1 d0. This makes them suitable for use as acoustic wall panels or ceiling tiles in residential, commercial or institutional settings in Singapore and elsewhere.

Ljuds™ panels are ideal for spaces needing sound control and a natural aesthetic: offices, conference rooms, schools, hospitality venues, lecture halls, auditoriums or renovation projects. They are effective when used on walls or ceilings to improve acoustics and indoor environmental comfort.