Timberix™

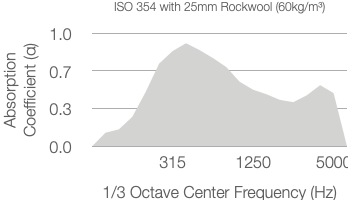

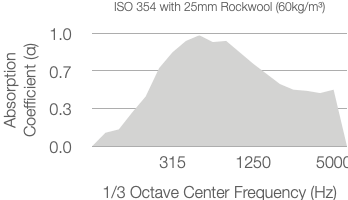

Timberix™ reduce echoes by trapping and diffracting sound in the grooves and perforation found on the surface. The sound that passes through the perforation is further absorbed by an acoustic substrate such as fibreglass or mineral wool, which reduces reverberation of the space.

Most Popular

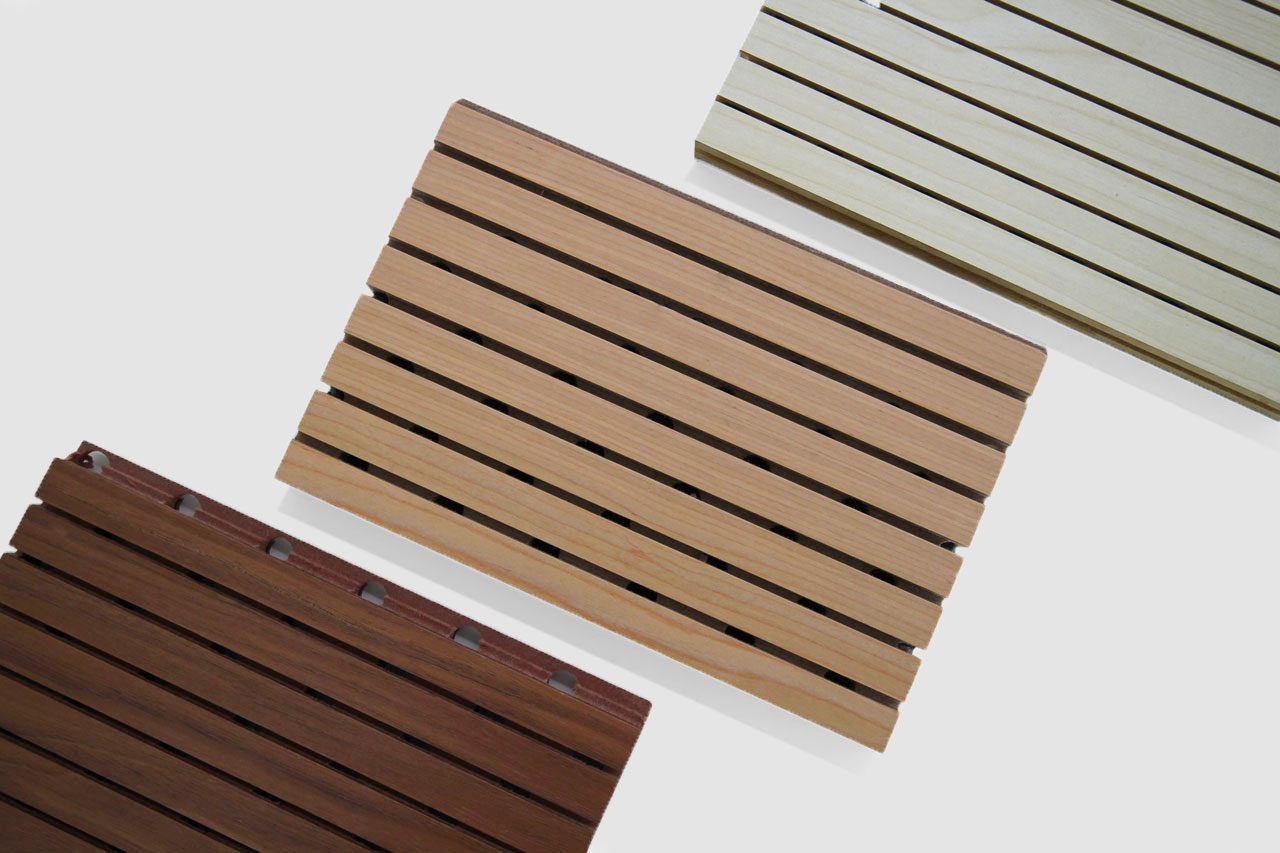

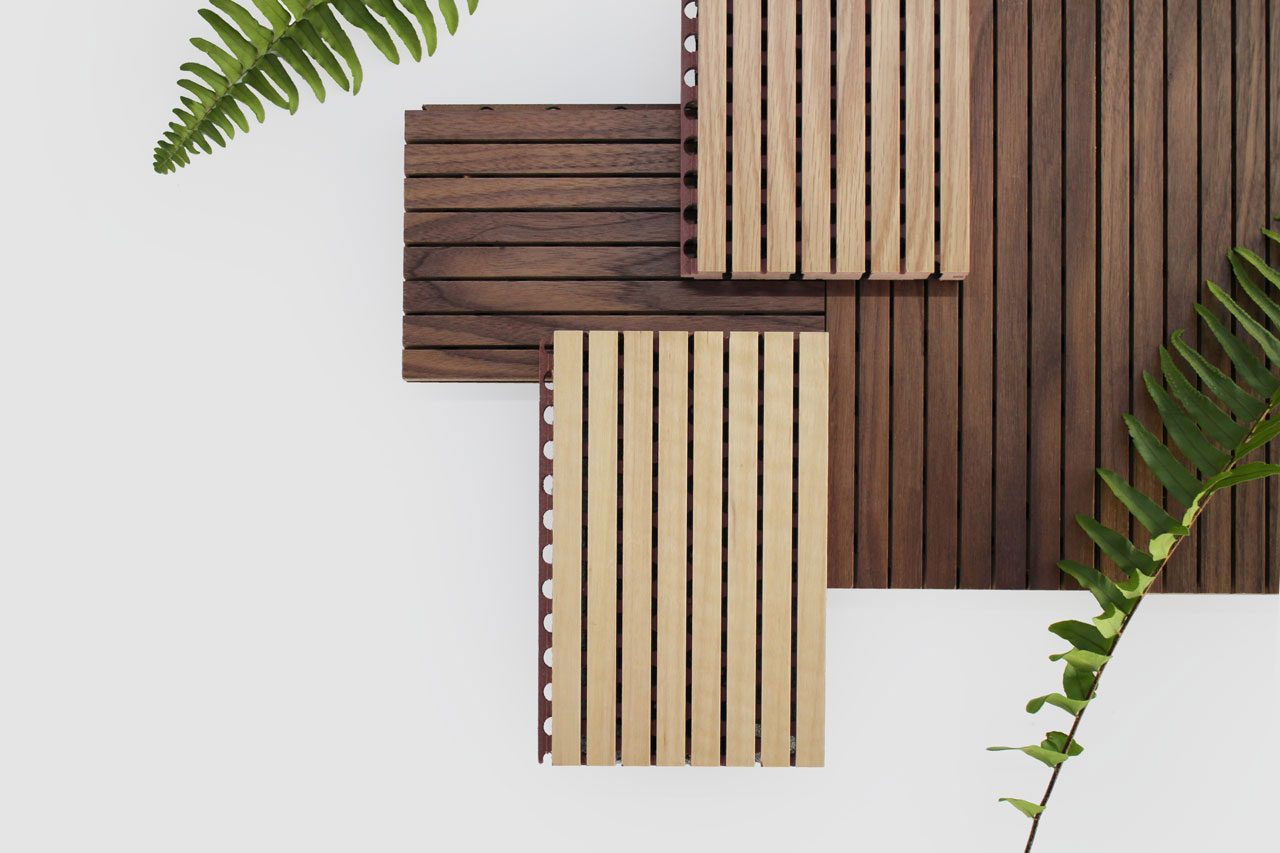

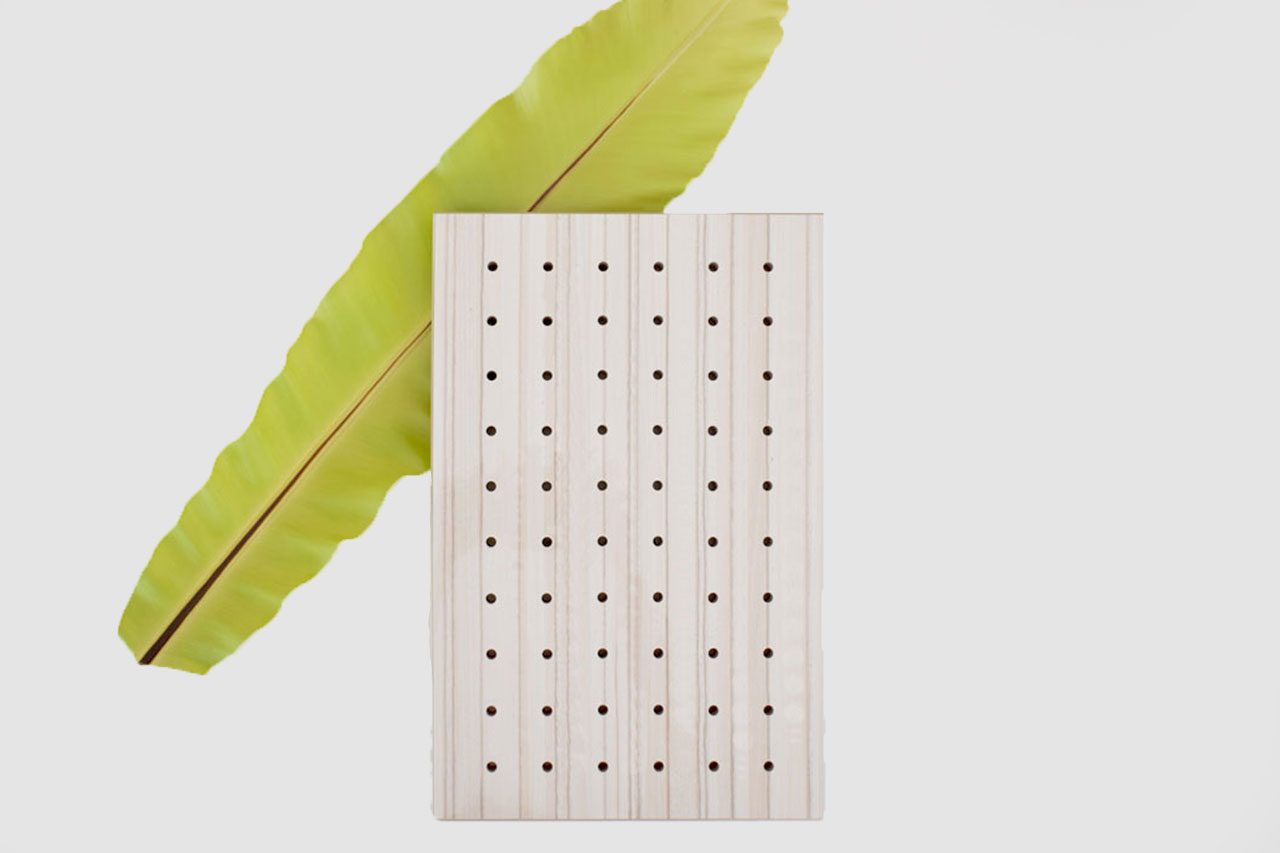

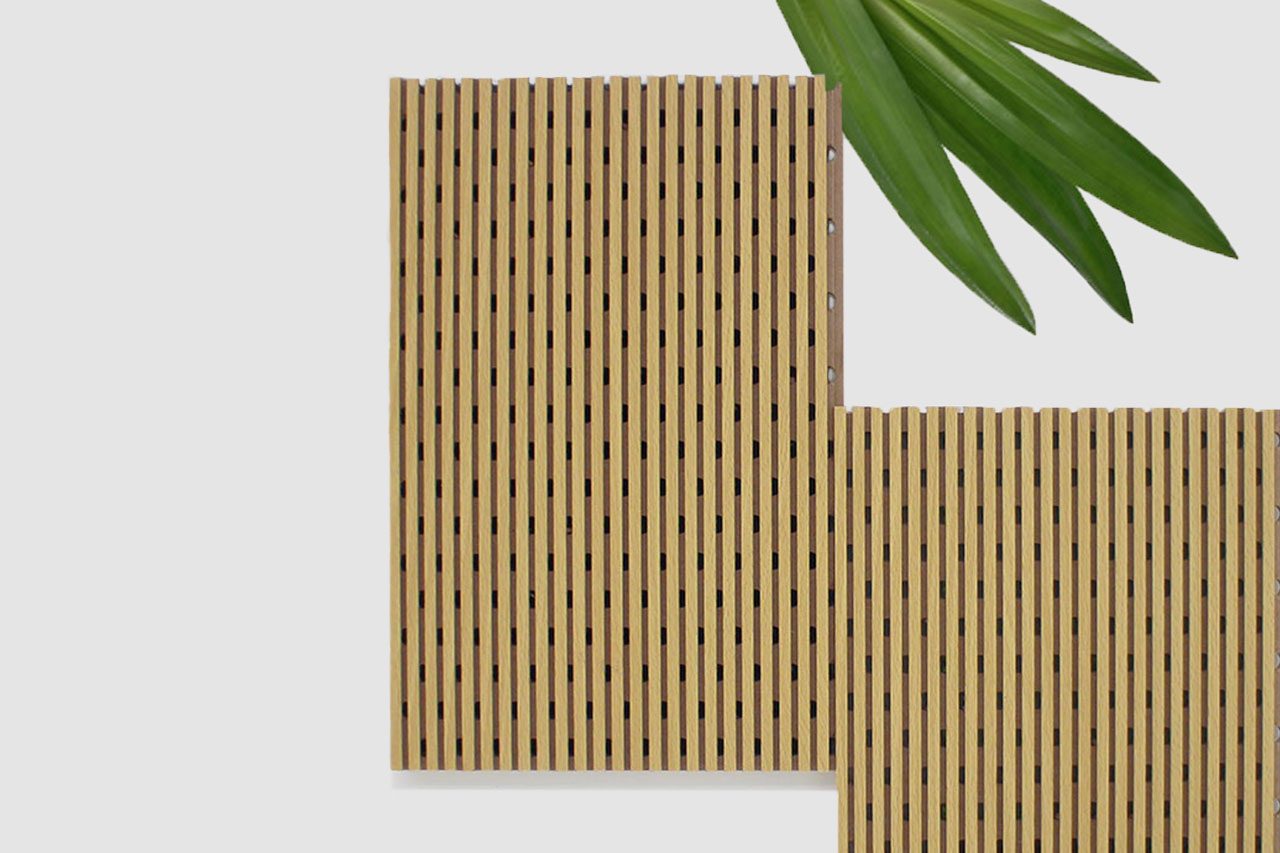

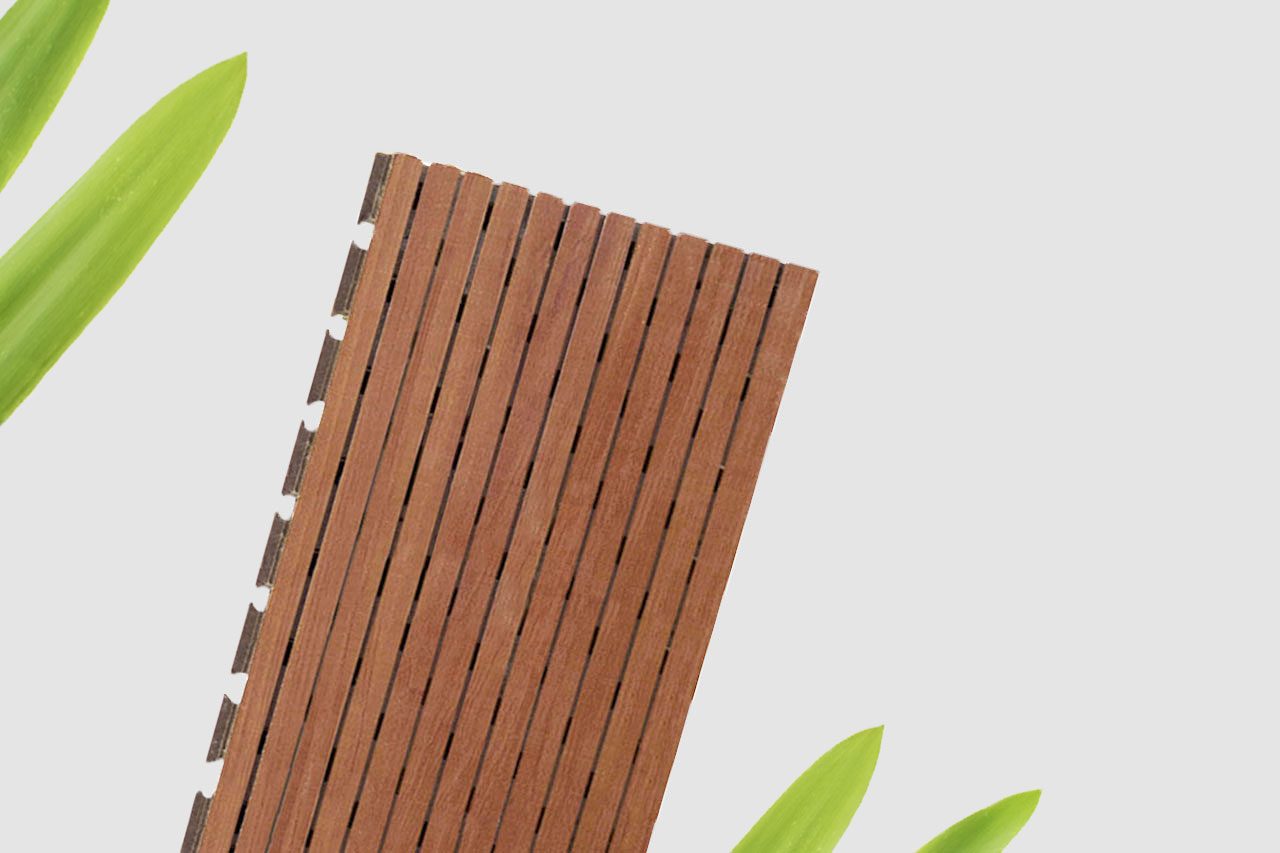

Grooved

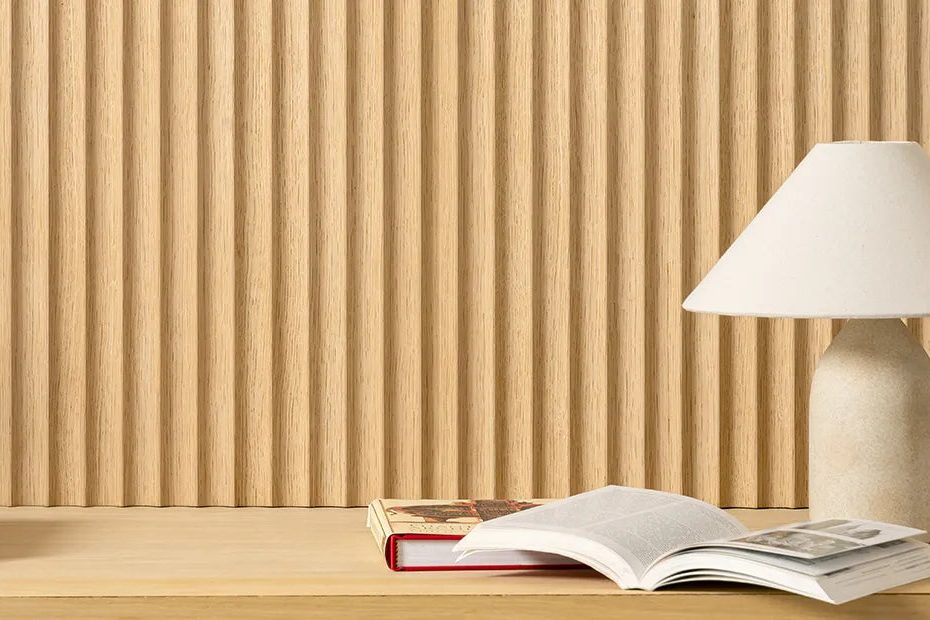

Timberix™ Grooved acoustic panel features slats and grooves with a machined tongue-and-groove joint for seamless joinery.

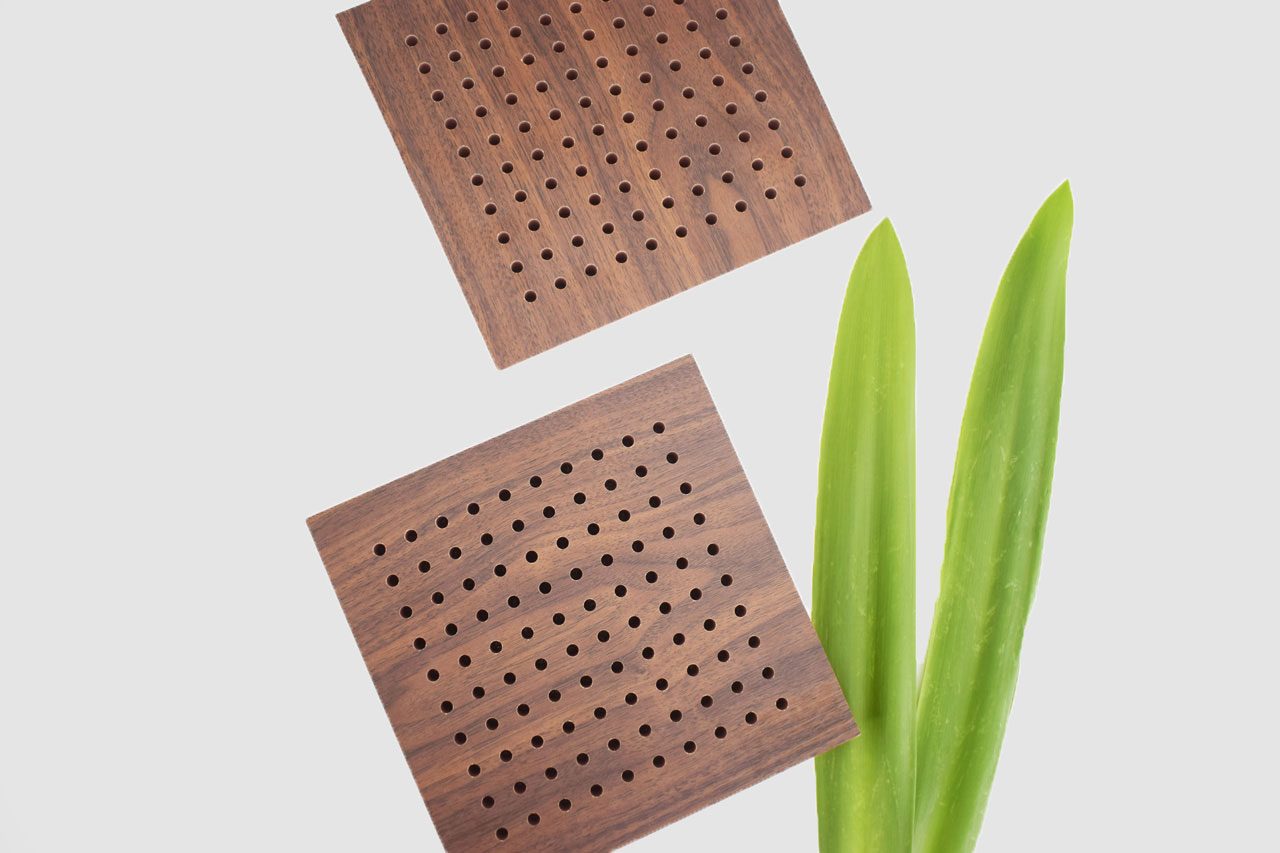

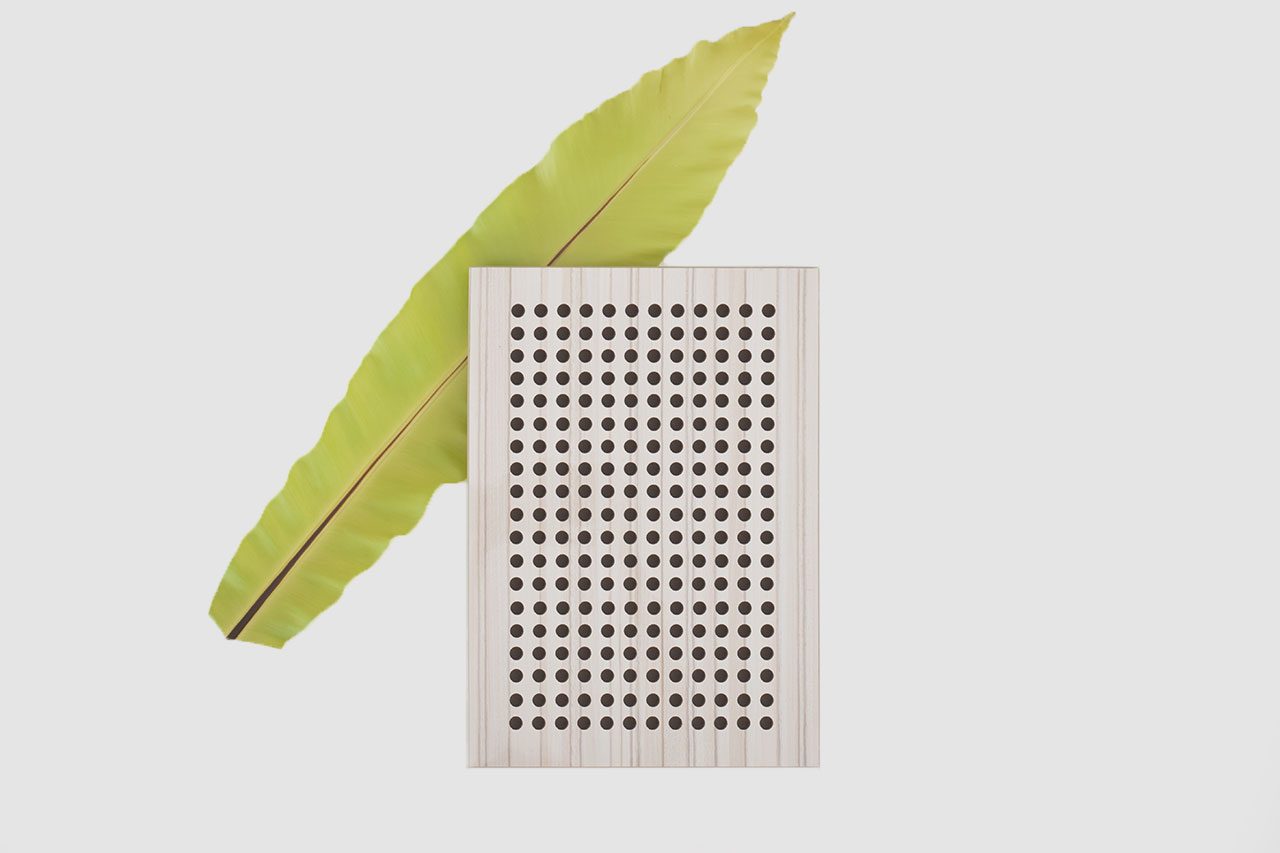

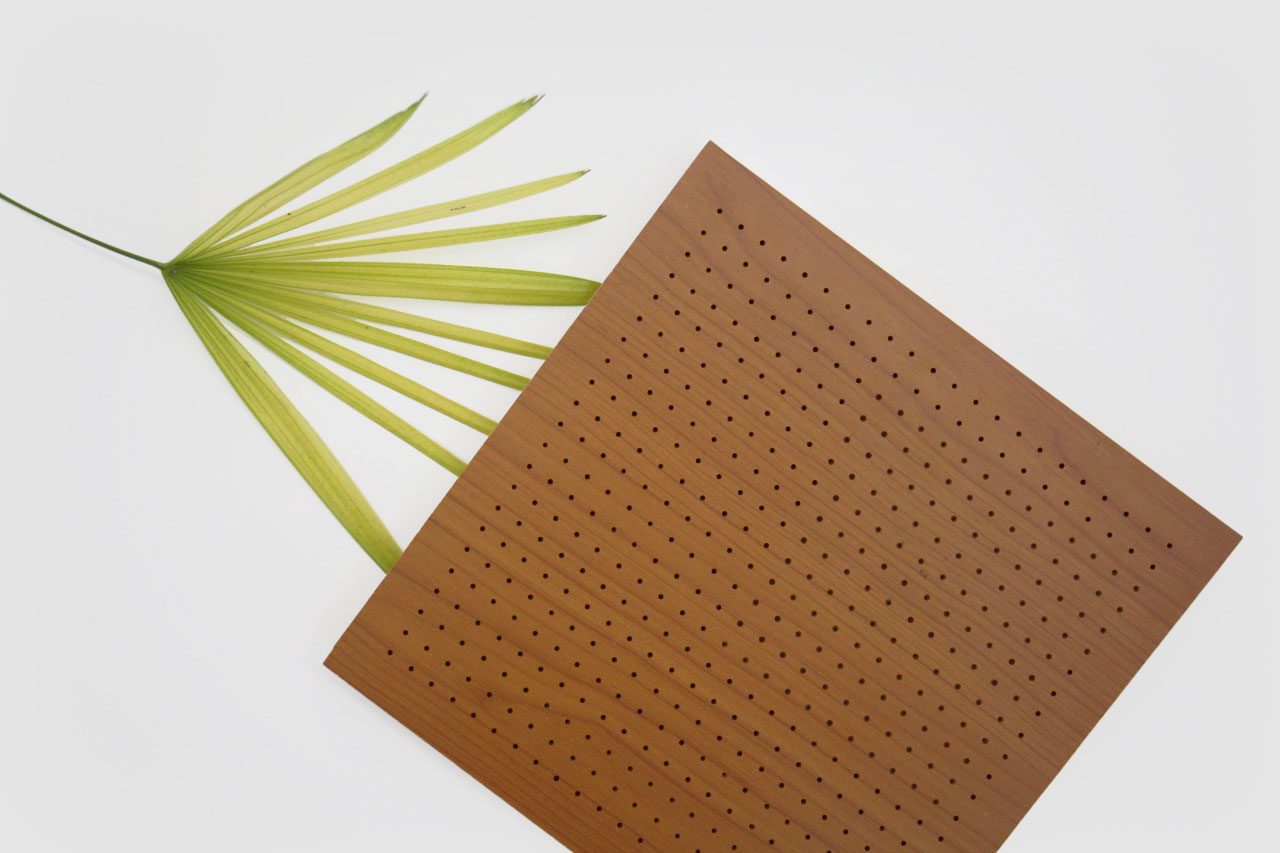

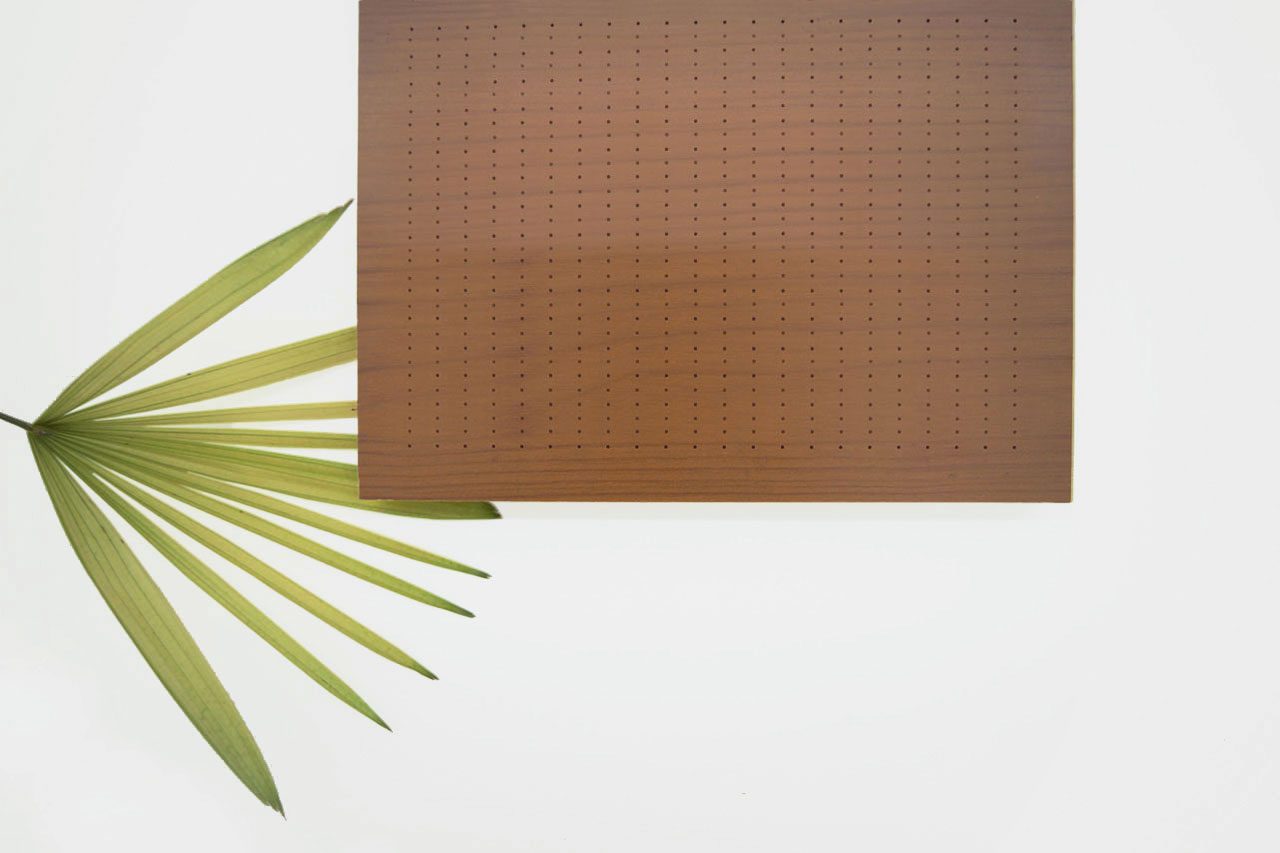

Perforated

Timberix™ Perforated panels feature a 2-layer perforation to trap and diffuse sound for enhanced acoustic performance.

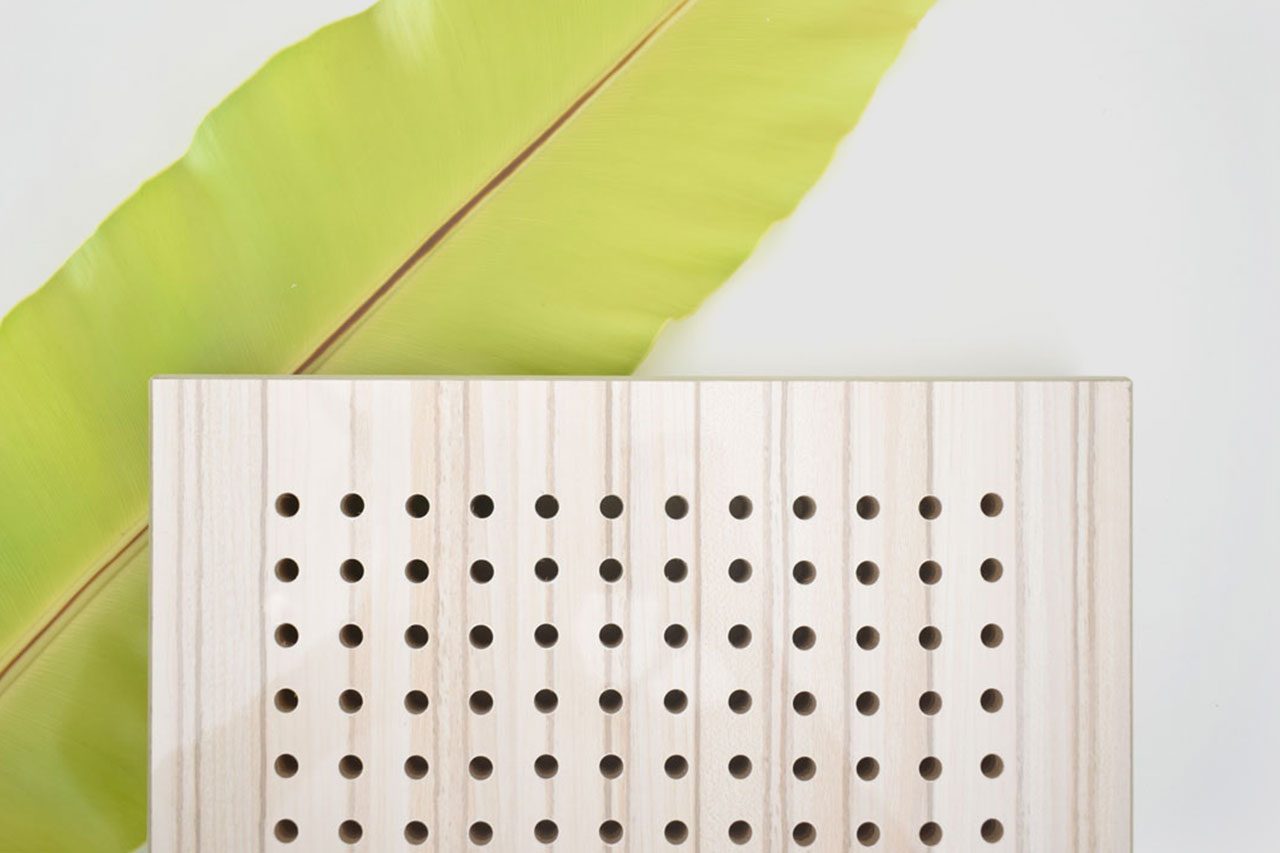

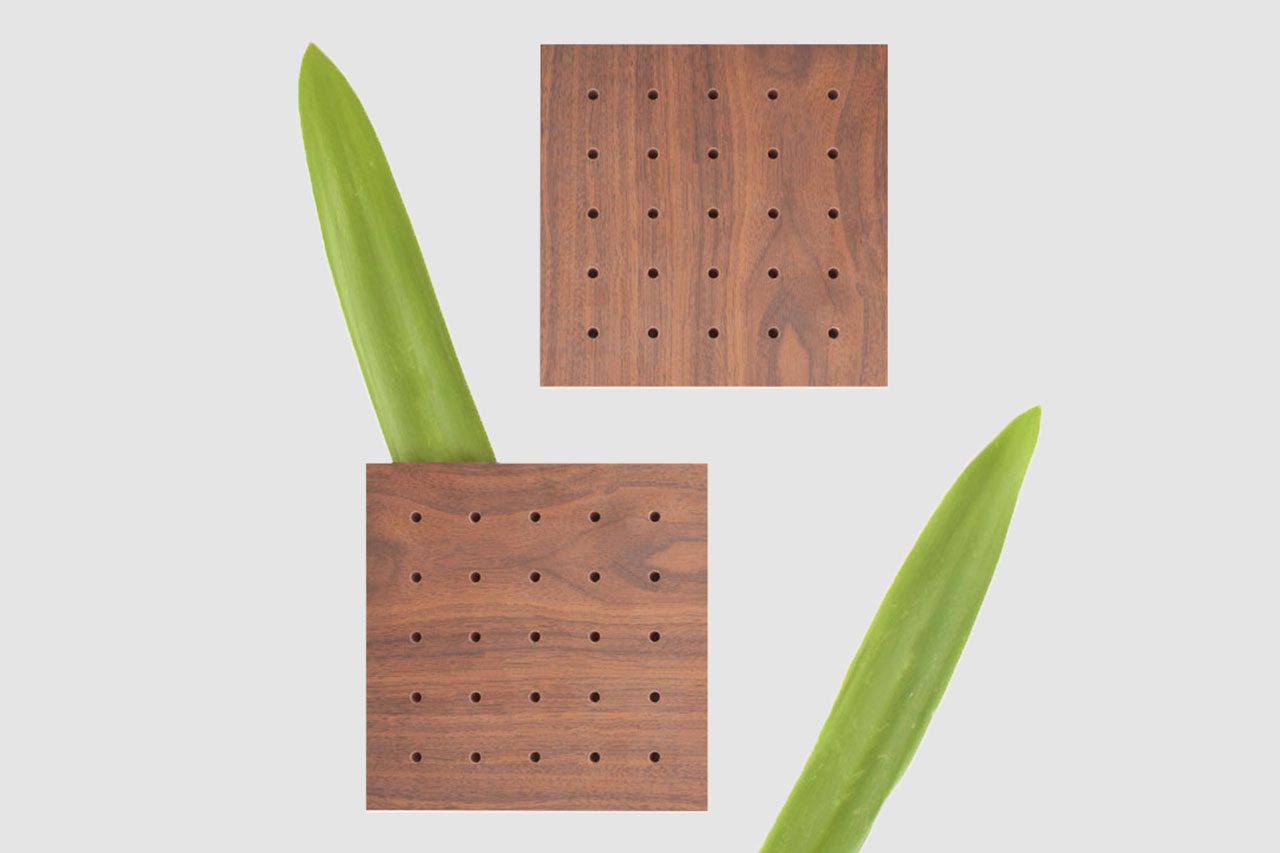

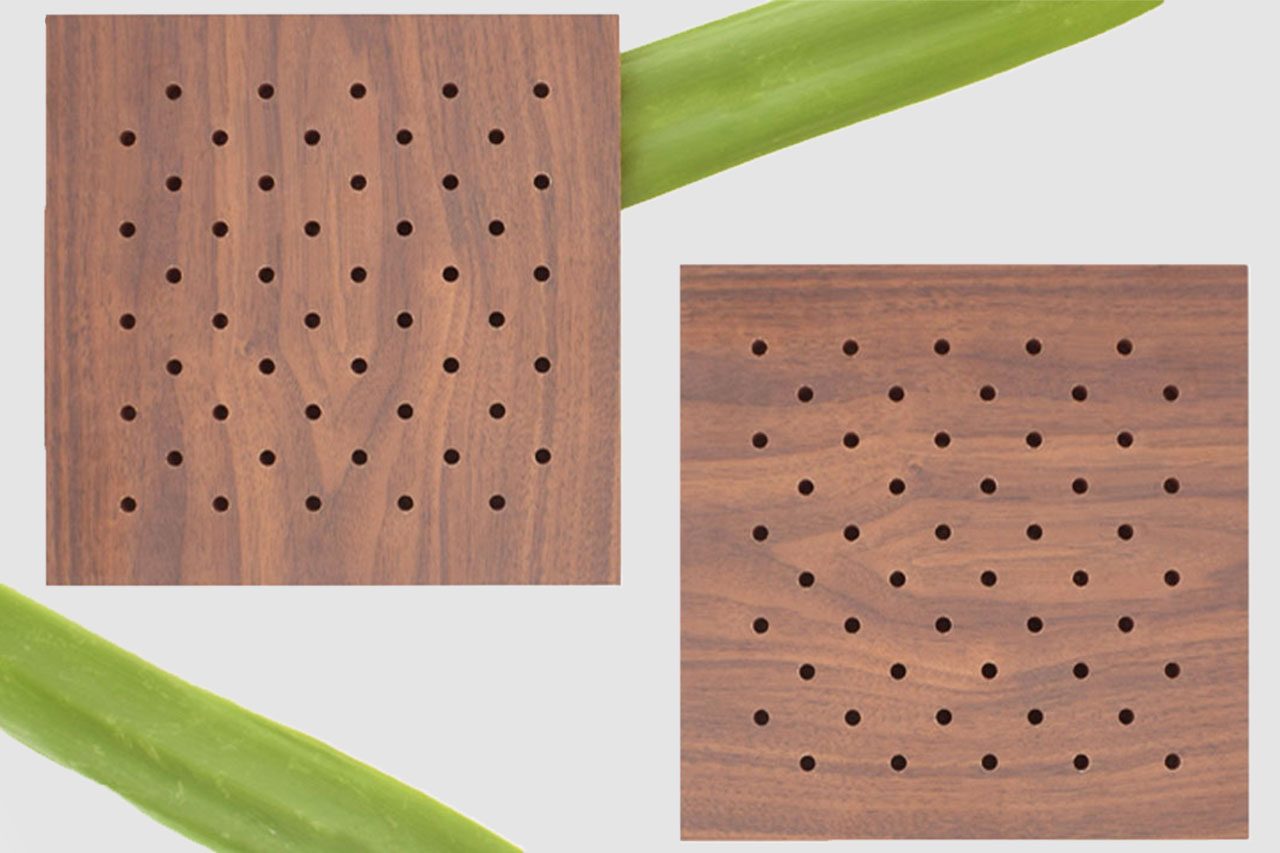

Microperforated

Timberix™ Microperforated are micro-holes only perceptible at short eye distance (+/- 250 000 holes/m2) and laminated on a 15mm thick MDF board.

Microperforated

Material: E1 MDF, FR MDF, MgO Composite Board

Structure: Base Material, Finishing & Fleece

Finishing: Melamine, Veneer, Laminate, Paint

Dimension: 2400mm x 128mm or 192mm

Standard Thickness: 12mm, 15mm, 18mm

Standard Pattern: 3.6-1.8-0.5, 8-8-1, etc.

-

Eco-Friendly Test:

EN 13986 = E1 -

Fire Classification Test:

EN 13501-1 = Class B -

Smoke Density Test:

EN 13501-1 = s1 d0

Grooved

Material: E1 MDF, FR MDF, MgO Composite Board

Structure: Base Material, Finishing & Fleece

Finishing: Melamine, Veneer, Laminate, Paint

Dimension: 2420mm x 128mm or 192mm

Standard Thickness: 12mm, 15mm, 18mm

Standard Pattern: 13-3, 14-2, 28/4, 59/5

-

Eco-Friendly Test:

EN 13986 = E1 -

Fire Classification Test:

EN 13501-1 = Class B -

Smoke Density Test:

EN 13501-1 = s1 d0

Perforated

Material: E1 MDF, FR MDF, MgO Composite Board

Structure: Base Material, Finishing & Fleece

Finishing: Melamine, Veneer, Laminate, Paint

Dimension: 2400mm x 128mm or 192mm

Standard Thickness: 12mm, 15mm, 18mm

Standard Pattern: 16-16-6, 32-32-6, etc.

-

Eco-Friendly Test:

EN 13986 = E1 -

Fire Classification Test:

EN 13501-1 = Class B -

Smoke Density Test:

EN 13501-1 = s1 d0

Grooved

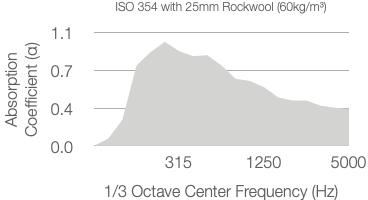

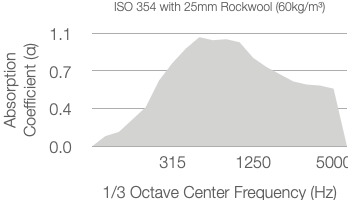

Grooved 12/4

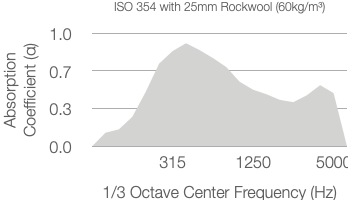

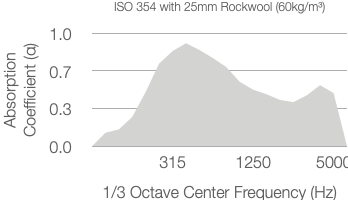

Timberix™ 12-4 panels reduce echoes by trapping sound and absorbing high and low frequencies.

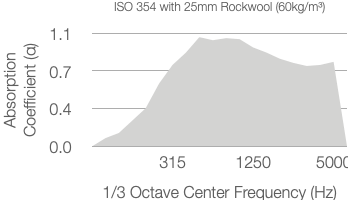

Grooved 13/3

Timberix™ 13-3 panels reduce echoes by trapping sound and absorbing high and low frequencies.

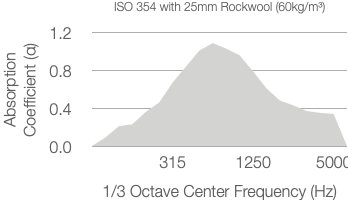

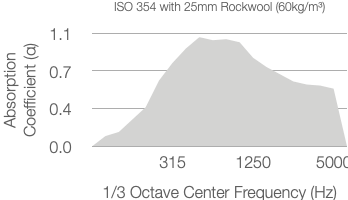

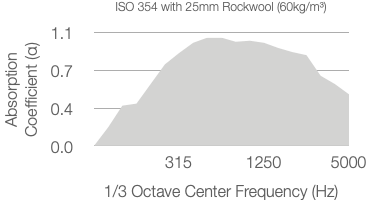

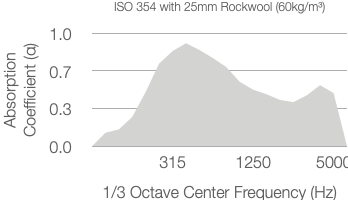

Grooved 14/2

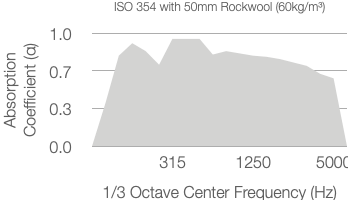

Timberix™ 14-2 panels reduce echoes by trapping sound, with 50mm rockwool absorbing high and low frequencies.

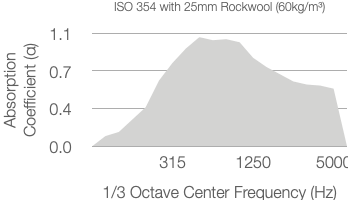

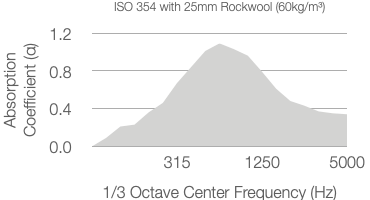

Grooved 28/4

Timberix™ 28-4 panels reduce echoes by trapping sound, with 50mm rockwool absorbing high and low frequencies.

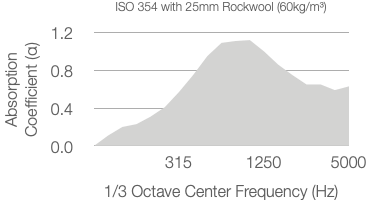

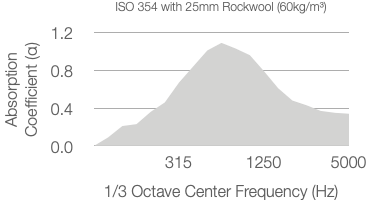

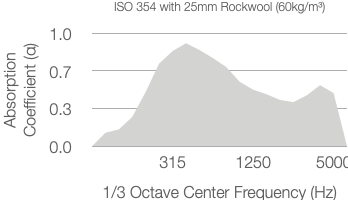

Grooved 59/5

Timberix™ 59-5 panels reduce echoes by trapping sound and absorbing high and low frequencies.

V-Grooved

Timberix™ V-grooved panels reduce echoes by trapping sound and absorbing high and low frequencies.

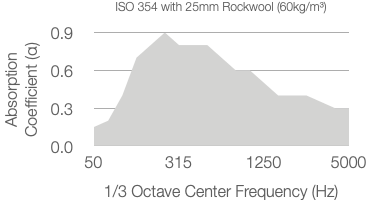

Perforated

Perforated E 16/16/6

Timberix™ E 16/16/6 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated E 16/16/8

Timberix™ E 16/16/8 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated E 16/16/10

Timberix™ E 16/16/10 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated E 32/32/6

Timberix™ E 32/32/6 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated E 32/32/8

Timberix™ E 32/32/8 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated V 16/16/6

Timberix™ V 16/16/6 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated V 16/16/8

Timberix™ V 16/16/8 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated V 32/32/6

Timberix™ V 32/32/6 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Perforated V 32/32/8

Timberix™ V 32/32/8 panels trap sound with a 2-layer perforation, while an acoustic substrate reduces reverberation.

Microgrooved

Microgrooved 5/3

Timberix™ 5-3 Microgrooved panels use smaller grooves to reduce echoes and absorb high-frequency sound.

Microgrooved 8/2

Timberix™ 8-2 Microgrooved panels use smaller grooves to reduce echoes and absorb high-frequency sound.

Microgrooved 8/3

Timberix™ 8-3 Microgrooved panels use grooves to reduce echoes and absorb frequencies.

Microgrooved 9/2

Timberix™ 9-2 Microgrooved panels use smaller grooves to reduce echoes and absorb high-frequency sound.

Milliperforated

Milliperforated E 4/4/1

Timberix™ E 4/4/1 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated E 8/8/1

Timberix™ E 8/8/1 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated E 8/8/2

Timberix™ E 8/8/2 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated E 8/8/3

Timberix™ E 8/8/3 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated E 16/16/3

Timberix™ E 16/16/3 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated V 4/4/1

Timberix™ V 4/4/1 Milliperforated panels trap sound with a 2-layer perforation and 50mm insulation to reduce reverberation.

Milliperforated V 8/8/1

Timberix™ V 8/8/1 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Milliperforated V 8/8/3

Timberix™ V 8/8/3 Milliperforated panels trap sound with a 2-layer perforation and an acoustic substrate to reduce reverberation.

Microperforated

Microperforated E 2/2/0.5

Timberix™ E 2/2/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Microperforated E 3/3/0.5

Timberix™ E 3/3/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Microperforated E 8/8/0.5

Timberix™ E 8/8/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Microperforated V 1.8/1.8/0.5

Timberix™ V 1.8/1.8/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Microperforated V 3.6/1.8/0.5

Timberix™ V 3.6/1.8/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Microperforated V 4/4/0.5

Timberix™ V 4/4/0.5 Microperforated panels trap sound with a 2-layer perforation and reduce reverberation using an acoustic substrate.

Special

Ribbed

Timberix™ Wooden Ribbed panels trap sound in slots, with an acoustic substrate reducing reverberation for high and low frequencies.

Fluted

Timberix™ Wooden Fluted Panels diffuse sound through surface slots, while an acoustic substrate absorbs noise to reduce reverberation.

Slotted

Timberix™ Wooden Slotted panels trap sound in surface slots, with an acoustic substrate reducing high and low frequency reverberation.

Baffle

Timberix™ Baffle reduces echoes by trapping sound in baffle gaps, with an acoustic substrate absorbing high and low frequency reverberation.

Dew

Timberix™ Dew Perforated wood panels have structured patterns designed for mid-range frequency absorption. Ideal for various spaces.

Fern

Timberix™ Fern perforated panels combine natural design with effective sound absorption, controlling echoes for optimal acoustic comfort.

Project Highlight

Timberix™ 20/4

The University Cultural Centre, is a world class performing arts centre that facilitates 22 student arts excellence groups in music, dance, theatre and film. The performance hall was designed to achieve an RT60 time of 1.8 – 2.5 seconds. Timberix grooved panels with grooves 20/4, and ugyen and walnut finish were installed onto the walls to achieve the reverberation time.

How Does Timberix™ Timber Acoustic Panel Work?

Timberix™ Timber Acoustic Panels enhance sound absorption using engineered timber slats, perforated wood surfaces, and high-quality natural wood cores. These systems improve sound control, thermal comfort, and overall acoustic quality in every room. Designed in line with architectural interiors, they elevate office and residential décor, resist moisture and mold risk, and deliver practical benefits for customers. As an innovation-driven company, Timberix™ develops timber acoustic solutions that balance acoustic performance, durability, and refined interior aesthetics.

Sound Absorption

In rooms with reflective surfaces and high ceilings, sound waves create echo and excessive reverberation that reduce speech clarity. Timberix™ Timber Acoustic Panels are engineered to absorb sound at the source, helping to control noise levels, improve sound quality, and create a more comfortable environment in offices, auditoriums, and other spaces.

Designed for Architects

Effective acoustics should blend seamlessly with interior design. Timberix™ Timber Acoustic Panels come in a wide range of wood finishes, groove profiles, and panel styles to suit modern offices and public spaces. These timber panels integrate sound control without disrupting the natural warmth and visual identity of the room.

Warranty Guaranteed

High-use environments require acoustic systems that last. Timberix™ Timber Acoustic Panels are engineered with durable, fire-rated, and eco-conscious materials to deliver consistent acoustic performance. Supported by reliable warranty protection, they provide long-term stability, thermal comfort, and peace of mind for customers.

Frequently Asked Questions

Timberix™ is a range of timber acoustic panels engineered to reduce echoes and reverberation. The panels use carefully designed grooves or perforations on their surface. When sound hits the panel, some of it is trapped or diffracted by the grooves or holes. The sound then passes through to an internal acoustic substrate, which absorbs the sound energy — thereby reducing noise and improving acoustic comfort.

There are multiple varieties of Timberix™ panels including grooved wood panels, perforated wood panels, and micro-perforated wood panels. Each type can be used for wall cladding or ceiling installations depending on the project. The panels are available in various standard dimensions and finishes, allowing them to serve as acoustic wall panels or ceiling tiles depending on design and acoustic needs.

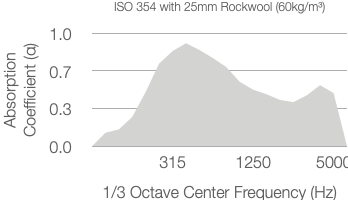

Timberix™ panels, when installed with an acoustic substrate, achieve a Noise Reduction Coefficient (NRC) in the range of roughly 0.3 to 0.75. This means they provide effective sound absorption and can significantly reduce reverberation, making them suitable for environments needing clearer speech, better sound control, or reduced echo.

Yes. Timberix™ uses base materials such as E1-rated MDF or fire-rated MDF, or composite boards, which comply with eco-friendly and safety standards. The product also meets fire-rated testing (EN 13501-1 Class B s1 d0) which makes it safer for indoor installations. These characteristics make Timberix™ suitable for homes, offices, and public buildings in Singapore or other humid urban environments.

For proper installation, the environment must be dry (temperature ≥ 10 °C and humidity between 40–60%). Panels should acclimatise on-site for at least 48 hours before installation. When installing, acoustic substrate is first applied, then panels are joined top-to-bottom and left-to-right. For veneer or wood-laminate finishes, care must be taken to match grain direction. After installation, it’s recommended to clean surface dust with compressed air or dry cloth. These steps help ensure long-term acoustic performance and avoid warping or moisture issues.